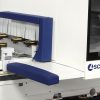

SCM Accord 25FXM CNC Machining Centre

The SCM Accord 25FXM CNC Machining Centre is designed for highly flexible productions requiring superior precision and finish quality regardless of component shape and dimensions.

Equipped with the high-performance SCM multifunction worktable in aluminum, guaranteeing high standards of accuracy. Ideal solution for boring-routing operations on solid wood components and panels of plastic, composites, resins and light alloys also with Nesting technology.

Manufacture – SCM

Condition – New

Price – POA

TOP FINISH QUALITY THANKS TO THE RIGID MOBILE PORTAL STRUCTURE

The rigid mobile portal structure, equipped with both front and rear sliding guides, ensures maximum precision and finish quality on the entire machining area. It is possible to process components of maximum length 6170 mm, width 2120 mm and thickness 250 mm.

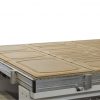

EXCLUSIVE PRECISION WITH THE SCM MULTIFUNCTION WORKTABLE

The SCM aluminum multifunction worktable ensures precision and reliability. Characterized by lasting perfect planarity, it does not deform despite changes in ambient factors such as temperature and humidity. For maximum precision, the worktable is worked directly in the cnc machining centre. Direct integrated vacuum and specially designed T-shaped grooves allow optimum locking and positioning of any type of support. Different possible fixtures: MPS suction cups, jigs, spoil board or locking devices.

EASY TO USE SMART TECHNOLOGY WITH 5 -AXIS MACHINING HEAD AND 3D SOFTWARE

Prisma Machining head with 5 interpolating axes enables processing of complex three-dimensional surfaces even in reduced space, thanks to its compact design. It is equipped with an electro-spindle, designed and manufactured by SCM, matching high power (up to 12 kW) and high speed (up to 24000 rpm) for optimal use in different applications.

Maestro 3D software allows to design and create threedimensional objects through powerful CAD tools in the easiest and quickest way.

ERGONOMICS AND SAFETY

The new safety system “Pro Speed” with horizontal photocells and new bumpers on the mobile protection (SCM patent), marries maximum accessibility to the work table and safety for the operator in the workpiece loading/unloading operations, whilst maximum speed and productivity are reached during machining.

| Function | Measurement |

|---|---|

| X-Axis Working Area | from 3650 to 6170mm |

| Y-Axis Working Area | from 1320 to 2120mm |

| Component Passage | 250mm |

| Electrospindle Power | from 12 to 15kW |

| Tool-Changer | from 10 to 44 nr. positions |

OPENING HOURS

Monday - Friday : 8:30 - 17:00

Saturday : by appointment

Sunday : closed

CONTACT

Tel : 01275 371 922

Email : info@mjmwoodmachines.com